- Blog Post

Trockenblockkalibrator vs. Temperaturkalibrierbad: Ein praktischer Leitfaden zur Auswahl

In der pharmazeutischen und biotechnologischen Validierung ist eine präzise Temperaturkalibrierung für die Qualitätssicherung von grundlegender Bedeutung. Jede Tätigkeit, die von genauen Temperaturmessungen abhängt, von Sterilisationszyklen bis hin zu Stabilitätsstudien, erfordert Kalibriergeräte, die Rückverfolgbarkeit und zuverlässige Leistung gewährleisten. Zwei häufig verwendete Referenzgeräte sind Trockenblockkalibratoren und Flüssigkeitstemperaturbäder. Beide überprüfen die Genauigkeit von Sensoren, funktionieren jedoch unterschiedlich und eignen sich für unterschiedliche Anwendungsfälle. Dieser Vergleich erläutert, wie die einzelnen Methoden funktionieren und wo sie in regulierten Umgebungen am besten eingesetzt werden können, wobei die Auswahl von der Geometrie der Sonde, der erforderlichen Unsicherheit, dem Durchsatz und der Frage abhängt, ob die Kalibrierung im Labor oder vor Ort durchgeführt wird.

Definition der beiden Ansätze

Was ist ein Trockenblockkalibrator?

Ein Trockenblockkalibrator (oder Trockenbrunnenkalibrator) erzeugt eine kontrollierte Temperatur durch Erhitzen oder Kühlen eines massiven Metallblocks mit präzisionsgefertigten Hohlräumen, in denen die Sonden sitzen. Da keine Flüssigkeit verwendet wird, sind diese Geräte kompakt und relativ wartungsarm, was sie für den mobilen und Vor-Ort-Einsatz geeignet macht.

Wichtigste Merkmale:

- Kompakt und tragbar: Ideal für Kalibrierungen vor Ort und in der Produktion, aber auch für den Einsatz im Kalibrierlabor geeignet

- Schnelle Stabilisierung

- Unterstützt sehr große Temperaturbereiche: Von kryogenen/ultraniedrigen Bedingungen bis hin zu Hochtemperaturanwendungen in einem Gerät.

- Kurze Umschaltzeiten zwischen den Sollwerten. Schnelle Aufheiz- und Abkühlraten

- Konsistente Positionierung der Sonde innerhalb des Einsatzes unterstützt wiederholbare Ergebnisse.

- Unterstützt die gleichzeitige Kalibrierung mehrerer Sensoren

- Geringeres Kontaminations- und Verschüttungsrisiko, da keine Tauchflüssigkeit erforderlich ist.

Trockenblöcke können aufgrund des reduzierten thermischen Kontakts eine höhere Unsicherheit für Sensoren mit atypischen Geometrien oder nicht passenden Durchmessern aufweisen; die Einstecktiefe und die richtige Auswahl des Einsatzes sind entscheidend.

Neben der Stabilität ist die radiale und axiale Homogenität des Kalibrierblocks entscheidend für eine minimale Kalibrierunsicherheit.

Was ist ein Temperaturkalibrierbad?

Temperaturkalibrierbäder oder Flüssigkeitsbäder (Tauchbäder) erzeugen ein stabiles, gleichmäßiges Temperaturfeld, indem sie ein gerührtes Medium (z. B. Wasser, Silikonöl oder Alkohol) zirkulieren lassen, in das die Sonden eingetaucht werden. Das direkte Eintauchen verbessert den thermischen Kontakt und die räumliche Gleichmäßigkeit, was die Messunsicherheit verringert. Daher sind Bäder die bevorzugte Wahl für komplexe Sondengeometrien.

Wichtige Merkmale:

- Hohe Gleichmäßigkeit und Langzeitstabilität: Die gerührte Flüssigkeit sorgt für eine gleichmäßige Temperaturverteilung mit geringen räumlichen Gradienten.

- Gut geeignet für komplexe oder große Sonden: Das Eintauchen sorgt für einen zuverlässigen thermischen Kontakt bei unregelmäßigen Formen und größeren Sensoren.

- Vor allem für den Laborgebrauch geeignet: Nicht für den mobilen Einsatz vorgesehen.

- Messunsicherheit: Hervorragender thermischer Kontakt und Homogenität reduzieren die erweiterten Unsicherheitsbudgets.

- Einfachere Handhabung ungewöhnlicher Sondenformen: Zur Stabilisierung der Sonden während des Eintauchens können spezielle Halterungen und Einsätze verwendet werden.

Flüssigkeitsbäder erfordern regelmäßige Flüssigkeitswechsel, Reinigung und Kontaminationskontrolle, da sich das Medium mit der Zeit zersetzen, verdunsten oder verunreinigen kann. Diese Faktoren beeinträchtigen die Temperaturstabilität, erhöhen die Messunsicherheit und machen Bäder für den mobilen oder Feldeinsatz unpraktisch. Bäder haben in der Regel auch längere Aufheiz- und Abkühlzeiten und erfordern möglicherweise einen Wechsel des Badmediums, um extrem niedrige bis sehr hohe Temperaturbereiche abzudecken, was den Durchsatz und die betriebliche Flexibilität einschränkt.

Vergleichende Analyse: Trockenblock vs. Temperaturbad

Um die richtige Kalibrierungsmethode auszuwählen, sollten Sie die für Ihre Anwendung relevanten Parameter bewerten: nutzbarer Temperaturbereich, erreichbare Unsicherheit, Sondenform, Durchsatz und ob die Kalibrierung im Labor oder vor Ort durchgeführt wird.

1. Temperaturbereich und Leistung

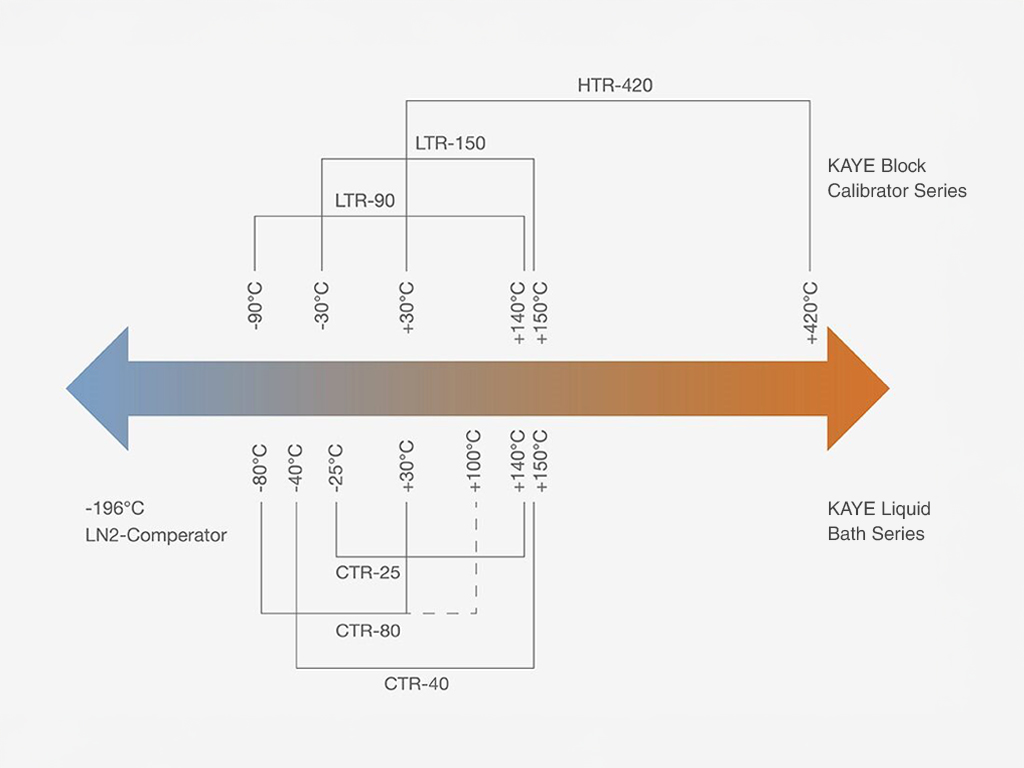

Trockenblockkalibratoren verwenden einen massiven, präzisionsgefertigten Metallblock mit Aussparungen zum Einführen der Sonde. Je nach Modell können Trockenblöcke sehr große Bereiche abdecken (im Fall von Kaye Temperature References sind Blöcke für sehr niedrige Temperaturen bis zu minus 90 °C oder hohe Temperaturen bis zu +420 °C erhältlich). Sie stabilisieren sich schnell und bieten eine gute Wiederholbarkeit, wenn die Sonden richtig in die Einsätze passen, aber ein unvollständiger thermischer Kontakt (nicht passende Durchmesser oder unzureichende Einstecktiefe) kann die Unsicherheit erhöhen.

Flüssigkeits-Tauchbäder zirkulieren ein gerührtes Medium (Wasser, Silikonöl usw.), um eine äußerst gleichmäßige thermische Umgebung zu schaffen. Je nach Badtyp und Flüssigkeit reichen die Bereiche von Kryokomparatoren (≈ −196 °C mit LN2-Systemen) bis hin zu Hochtemperatur öl- oder Salzbädern; hochpräzise Salzbäder können etwa +550 °C erreichen. Beispiel: Bestimmte Geräte der Kaye CTR-Serie (z. B. CTR-40) arbeiten im Bereich von minus 40 °C bis +150 °C, während das Kaye CRT-80 minus 80 °C bis +30 °C abdecken kann, ohne dass die Badflüssigkeit gewechselt werden muss.

Praktischer Hinweis: Keine einzelne Tauchflüssigkeit deckt den Bereich von kryogenen bis zu sehr hohen Temperaturen effektiv ab. Um Extreme abzudecken, muss in der Regel das Badmedium gewechselt oder separate Systeme verwendet werden.

2. Sensorkompatibilität und Eintauchtiefe

Das richtige Eintauchen ist für eine genaue Kalibrierung entscheidend: Das Sensorelement muss vollständig eingetaucht und vom Referenzmedium umgeben sein, um einen korrekten thermischen Kontakt zu gewährleisten. Eine gängige Richtlinie lautet, die Sonde mindestens 10- bis 15-mal so tief wie ihr Durchmesser einzutauchen (und das Sensorelement immer vollständig zu bedecken), aber die erforderliche Tiefe immer mit dem Sensor- und Gerätehersteller zu bestätigen.

- Trockenblockkalibratoren

Am besten geeignet für gerade Sonden mit kleinem Durchmesser wie RTDs und Thermoelemente. Sie liefern wiederholbare Ergebnisse, wenn der Einsatz und die Eintauchtiefe zur Sonde passen, werden jedoch nicht für empfindliche Instrumente (z. B. Glasthermometer) oder Sonden empfohlen, die vollständig eingetaucht werden müssen. Die richtige Auswahl des Einsatzes und eine gleichbleibende Eintauchtiefe sind unerlässlich, um Wärmeübertragungsfehler zu minimieren. - Temperaturkalibrierbäder

Flüssigkeitsbäder sind ideal für größere oder unregelmäßig geformte Sonden – Hygieneproben, Flanschsensoren und drahtlose Datenlogger –, da sie ein vollständiges Eintauchen des Messelements (und gegebenenfalls der Elektronik) ermöglichen, um eine möglichst geringe Messunsicherheit zu erreichen. Das Eintauchen sorgt für einen hervorragenden thermischen Kontakt und eine gleichmäßige Temperaturverteilung, erfordert jedoch geeignete Halterungen oder Klemmen und Sorgfalt, um eine Bewegung der Sonde, den Auftrieb des Sensors (Schwimmen) oder den Kontakt mit den Behälterwänden zu verhindern.

Praktischer Hinweis: Dokumentieren Sie die Eintauchtiefen und die Auswahl der Einsätze in Ihren SOPs und überprüfen Sie alle Faustregeln anhand der Empfehlungen des Herstellers, um Rückverfolgbarkeit und geringe Unsicherheit zu gewährleisten.

3. Chargengröße und Durchsatz

Trockenblockkalibratoren:

Die Anzahl der Sensoren, die Sie gleichzeitig kalibrieren können, hängt in erster Linie von der Größe des Kalibrierblocks und der Anzahl der verfügbaren Kalibriervertiefungen ab. Kleine, tragbare Systeme mit austauschbaren Einsätzen ermöglichen in der Regel die parallele Überprüfung einer Handvoll Temperatursensoren, während speziell entwickelte Thermoelement-Kalibriereinheiten, beispielsweise das Kaye LTR-150 oder HTR-420, bis zu 48 Thermoelemente parallel kalibrieren können.

Temperaturkalibrierbäder:

Die Kapazität für die parallele Sensorkalibrierung wird weitgehend durch die Öffnungsgröße und das Gesamtvolumen des Bades bestimmt. Kleine Tauchbäder bieten in der Regel nur Platz für eine Handvoll Sonden, während hochwertige Laborbäder mehrere Dutzend gleichzeitig aufnehmen können. Flexible Temperatursensoren (z. B. Thermoelemente) erfordern oft zusätzliche mechanische Halterungen oder Klemmen, um Auftrieb zu verhindern und ein stabiles Eintauchen zu gewährleisten; diese Halterungen reduzieren den nutzbaren Platz und können daher die Gesamtzahl der Sonden begrenzen, die gleichzeitig kalibriert werden können.

4. Tragbarkeit und Arbeitsumgebung

- Trockenblockkalibratoren:

Kompakt, leicht und flüssigkeitsfrei. Ideal für die Kalibrierung vor Ort in Fertigungsbereichen oder Außenbereichen, wo Mobilität, schnelle Einrichtung und geringer Wartungsaufwand wichtig sind. Da sie keine Tauchflüssigkeit enthalten, besteht keine Gefahr des Verschüttens und die Logistik wird vereinfacht. - Temperaturbäder:

In der Regel stationäre Tischsysteme, die einen speziellen Laborraum und eine spezielle Handhabung von Flüssigkeiten erfordern. Bäder eignen sich am besten für kontrollierte Laborumgebungen, in denen langfristige Stabilität, hervorragende Gleichmäßigkeit und hochpräzise Kalibrierung Priorität haben; für den routinemäßigen Einsatz im Außendienst sind sie nicht unbedingt praktisch.

5. Genauigkeit und Rückverfolgbarkeit

Unabhängig davon, ob ein Trockenblockkalibrator oder ein Flüssigkeits-Tauchbad verwendet wird, wird die Kalibrierungsgenauigkeit stark von mehreren Schlüsselfaktoren beeinflusst:

- Stabilität:

Geräte, die zur Kalibrierung von Temperatursensoren für die Validierung thermischer Prozesse in GxP- -Umgebungen verwendet werden, sollten bei jedem Kalibrierungs-Sollwert eine Temperaturstabilität von mindestens ±0,01 °C (oder besser) aufweisen.

- Homogenität (radial und horizontal)

Bei Trockenblockkalibratoren sollte eine Homogenität in der Größenordnung von ±0,1 °C sowohl radial als auch horizontal angestrebt werden; Tauchbäder (Flüssigkeit) können eine viel höhere Gleichmäßigkeit erreichen, oft besser als ±0,01 °C.

Hinweis: Dies sind Richtwerte. Die tatsächliche Leistung hängt vom Modell, den Einsätzen, der Tauchflüssigkeit und der Einrichtung ab. Überprüfen Sie immer die erforderlichen Spezifikationen im Produktdatenblatt und dokumentieren Sie die gemessene Stabilität/Homogenität in Ihren Validierungsunterlagen.

- Eintauchtiefe:

Unabhängig vom Kalibriergerät muss die richtige Eintauchtiefe für den zu kalibrierenden Sensor sichergestellt werden.

- Wärmeübertragung zwischen Kalibrator und Sensor:

Flüssigkeitsbäder bieten hier natürlich eine überlegene Leistung, da die Sonde in direktem Kontakt mit dem gerührten Medium steht. Bei Trockenblockkalibratoren ist es daher unerlässlich, auf den jeweiligen Sensor abgestimmte Kalibriereinsätze zu verwenden, um Fehler aufgrund eines suboptimalen Wärmekontakts (z. B. Luftspalte) zu minimieren. Achten Sie auf die richtige Auswahl der Einsätze und eine gleichmäßige Einstecktiefe, um Unsicherheiten im Zusammenhang mit der Wärmeübertragung zu reduzieren. - Kalibrierung anhand eines externen, rückführbaren Temperaturstandards:

In der Praxis verbessert die Verwendung eines externen, rückführbaren Temperaturstandards, beispielsweise des Kaye IRTD-400, die Gesamtkalibriergenauigkeit und erleichtert den Nachweis der Rückführbarkeit Ihrer Kalibrierergebnisse auf nationale Messstandards. Stellen Sie sicher, dass das Kalibrierzertifikat des Standards aktuell ist und seine Unsicherheit in Ihrem Messunsicherheitsbudget berücksichtigt wird.

Auswahl des richtigen Werkzeugs: Praktische Anwendungen und neue Innovationen

In fortschrittlichen thermischen Validierungsumgebungen kombiniert die Kalibrierungstechnologie zunehmend Präzisionstechnik, Datenintelligenz und Prozessintegration. Pharma- und Biotech-Teams suchen nach messtechnisch rückführbaren, automatisierten und vernetzten Systemen, die Reproduzierbarkeit, Datenintegrität und die Einhaltung von Vorschriften an mehreren Standorten unterstützen.

Moderne Kalibriereinheiten bieten die für Validierungsaufgaben erforderliche Stabilität, Gleichmäßigkeit und Messgenauigkeit. In Verbindung mit Software unterstützen sie automatisierte Kalibrierungs- und Verifizierungsläufe, deren Ergebnisse direkt in Validierungssysteme eingespeist werden. Die verfügbaren Temperaturbereiche decken Anwendungen wie die Qualifizierung von Impfstofflagern, die Validierung von Gefriertrocknungsprozessen und die Überprüfung von Bioreaktorprozessen sowie die Vor-Ort-Validierung von Autoklaven, Depyrogenisierungstunneln und Klimakammern ab.

Es entstehen hybride Kalibratorarchitekturen, die Trocken- und Flüssigkeitsmodi in einer einzigen Plattform kombinieren und Arbeitsabläufe sowohl für Konduktions- als auch für Tauchsensoren ermöglichen. Diese hybriden Designs können Multisensorprogramme vereinfachen und mit fortschrittlichen Regelalgorithmen unter kontrollierten Bedingungen (modellabhängig) außergewöhnlich niedrige Gradienten aufrechterhalten.

Nachhaltigkeit und Effizienz prägen ebenfalls das Systemdesign: Beispiele hierfür sind Energierückgewinnungsschleifen, umweltfreundlichere Wärmeträgerflüssigkeiten und adaptive Standby-Modi, die den CO2-Fußabdruck reduzieren und gleichzeitig die Betriebsbereitschaft gewährleisten.

Praktische Anleitung: Wählen Sie das Toolset, das zu Ihrer Anwendung passt (Labor vs. Feld, Einzel- vs. Batch-Sonden, Sondenform und Unsicherheitsanforderungen), überprüfen Sie die Leistungsangaben anhand der Datenblätter des Herstellers und bestätigen Sie die Ergebnisse durch interne Verifizierungsläufe.

Der geschäftliche Nutzen einer fundierten Auswahl

Die Wahl zwischen einem Trockenblockkalibrator und einem Temperaturkalibrierbad ist eine strategische Entscheidung, die sich auf die Validierungseffizienz, die Ressourcennutzung und die langfristige Compliance auswirkt. In regulierten Pharma- und Biotech-Umgebungen beeinflusst die von Ihnen gewählte Kalibrierungsmethode nicht nur die Messgenauigkeit, sondern auch die Auditbereitschaft und die Fähigkeit, die Produktqualität zu schützen.

Wenn die Kalibrierungshardware auf die Anforderungen des Arbeitsablaufs abgestimmt ist, profitieren Unternehmen von konkreten betrieblichen Vorteilen: weniger Ausfallzeiten, weniger Wiederholungstests und eine bessere Geräteleistung. Lösungen, die Portabilität mit labortechnischer Präzision verbinden (z. B. die thermischen Kalibrierungsprodukte von Kaye), können zu einer höheren Datenintegrität und Reproduzierbarkeit beitragen.

Aus geschäftlicher Sicht unterstützt der richtige Kalibrierungsansatz:

- Einhaltung gesetzlicher Vorschriften: Rückverfolgbare, wiederholbare Kalibrierung, die zur Erfüllung der aktuellen Kalibrierungsanforderungen beiträgt

- Betriebskontinuität: Weniger Unterbrechungen durch zuverlässige, effiziente Kalibrierungswerkzeuge und Arbeitsabläufe.

- Nachhaltigkeit: Reduzierung von Abfall und Energieverbrauch durch moderne, effiziente Kalibrierungstechnologien.

Die Auswahl der geeigneten Kalibrierungstechnologie stärkt die wissenschaftliche Genauigkeit und die betriebliche Ausfallsicherheit und trägt so zur Gewährleistung von Konsistenz, Compliance und langfristiger Zuverlässigkeit bei.

Zusammenfassung

Die Wahl zwischen einem Trockenblockkalibrator und einem Flüssigkeitskalibrierbad sollte auf einer strukturierten Bewertung basieren, um eine zweckmäßige Leistung und die Einhaltung gesetzlicher Vorschriften sicherzustellen:

- Definieren Sie den erforderlichen Temperaturbereich

Identifizieren Sie Geräte und, bei Bädern, geeignete Flüssigkeiten, die zusammen den von Ihnen benötigten Betriebsbereich abdecken. - Bewerten Sie die Sensortypen und die erforderliche Eintauchtiefe

Bäder bieten die größte Flexibilität für unregelmäßige oder große Sonden; Trockenblockkalibratoren eignen sich gut für gerade Sonden mit kleinem Durchmesser (RTDs, Thermoelemente). Bestätigen Sie die erforderliche Eintauchtiefe immer mit dem Sensor- und Gerätehersteller. - Bestimmen Sie den Kalibrierungsdurchsatz

Bestimmen Sie die Anzahl der parallel zu kalibrierenden Sensoren. Bei Trockenblockkalibratoren sind sensorspezifische Einsätze erforderlich, um die Wärmeübertragung zu optimieren und einen korrekten Sitz zu gewährleisten; bei Tauchbädern verwenden Sie spezielle Halterungen oder Klemmen, um die Sonden sicher im Badmedium zu fixieren. Die Auswahl der Einsätze und Halterungen beeinflusst die erreichbare Unsicherheit und wirkt sich auch darauf aus, wie viele Sonden gleichzeitig kalibriert werden können. - Bewertung der Arbeitsumgebung

Entscheiden Sie, ob die Kalibrierungen vor Ort (am Gerät oder an der Produktionslinie) oder in einem klimatisierten Kalibrierlabor durchgeführt werden sollen. Dies bestimmt, ob tragbare Systeme erforderlich sind. Bewerten Sie auch die Kontaminationsrisiken – sowohl die potenzielle Kontamination des zu prüfenden Sensors als auch der Umgebung, in der die Kalibrierung stattfindet – sowie alle standortspezifischen Einschränkungen (Anforderungen an Reinräume/klassifizierte Bereiche, Zugang, Stromversorgung, Auffangvorrichtungen für verschüttete Flüssigkeiten). Diese Faktoren sollten die Auswahl der Geräte, die Befestigung und die SOPs bestimmen. - Legen Sie Genauigkeits- und Unsicherheitsziele fest

Legen Sie im Voraus die erforderliche Stabilität, räumliche Homogenität (radial/horizontal) und akzeptable Unsicherheit fest, damit die Auswahl der Geräte Ihren Kalibrierungsgenauigkeitszielen entspricht. - Verwendung eines externen, rückführbaren Temperaturstandards:

Die Verwendung eines externen, rückführbaren Sekundärstandards verbessert in der Regel die erreichbare Kalibriergenauigkeit und trägt dazu bei, die Gesamtmessunsicherheit zu reduzieren.

Empfohlene Produkte

Hybride Temperaturkalibratoren

Trockenblockkalibratoren

Flüssigkeitskalibrierbäder

Temperaturreferenzstandard

Diese Produkte stehen für Kayes umfassenden Ansatz zur Temperaturkalibrierung und bieten Genauigkeit, Zuverlässigkeit und vollständige Rückverfolgbarkeit für Fachleute im Bereich der thermischen Validierung, die in regulierten Branchen tätig sind.

Fazit

Zusammenfassend lässt sich sagen, dass die Auswahl der richtigen Kalibrierungslösung, sei es Trockenblock, Flüssigkeitsbad oder Hybrid, eine zuverlässige, rückverfolgbare und konforme Temperaturvalidierung gewährleistet. Jedes System unterstützt Genauigkeit und Zuverlässigkeit in seiner einzigartigen Anwendungssituation.

Die Kalibrierungstechnologien von Kaye wurden entwickelt, um Fachleuten dabei zu helfen, gesetzliche Vorschriften und Leistungsstandards sicher zu erfüllen.

Kontaktieren Sie uns noch heute, um eine Demo anzufordern und das ideale Kalibriersystem für Ihren Betrieb zu besprechen.