When it comes to high-precision thermal validation in closed chambers—such as depyrogenation tunnels, drying ovens, or high-temperature test environments—real-time data loggers are indispensable tools. They offer unmatched flexibility in handling and placement while enabling continuous monitoring and validation. However, like all technologies, they face limitations—especially when operating in extreme heat.

Most real-time data loggers are powered by lithium-based batteries, which are only rated up to +140°C. Even high-performance lithium batteries carry the risk of explosion or leakage when exposed to temperatures beyond this threshold. So, the question arises:

Can real-time data loggers be used safely in environments exceeding +140°C?

The Answer: Yes—With a Smart Thermal Protection Solution

Kaye, a leader in thermal validation solutions, has developed an innovative approach that pushes the temperature barrier. The Kaye ValProbe RT® real-time data logger, when used alongside the specially designed high-temperature insulation canister, can be safely deployed at extreme temperatures—up to +360°C.

ValProbe RT® + High-Temperature Insulation Canister: A Powerful Duo

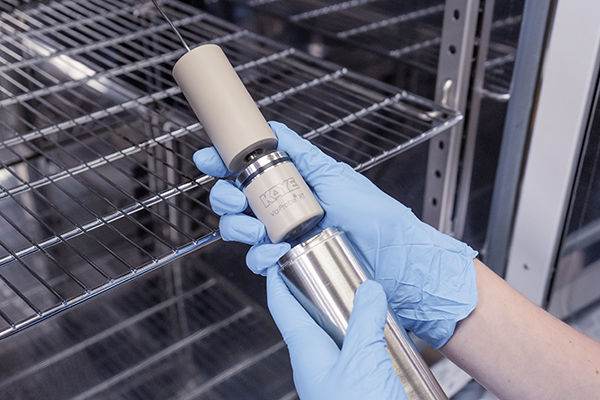

The ValProbe RT® unit itself is equipped with temperature-optimized lithium batteries capable of performing up to +140°C. To break through that ceiling, Kaye introduced a compact, flat, stainless steel insulation canister designed to shield the logger from excessive heat exposure.

Key Features of the Insulation Canister:

- Compact Size: Only 45 mm in diameter and 149 mm in length—ideal when working in space-constrained environments.

- Durability: Constructed from robust 316 stainless steel for strength and longevity.

- Smart Design: Utilizes vacuum-sealed insulating materials to extend operational temperature range.

- Compatibility: Suitable for single-, dual-, and five-channel ValProbe RT® data loggers using flexible temperature probes.

Step-by-Step Guide: How to Use the Insulation Canister

Using the insulating canister is simple and secure. Follow these steps to ensure your logger is protected in high-temperature environments:

1. Open the Canister:

Unscrew the protective cap by pressing down and rotating counterclockwise.

2. Prepare the Logger:

Slide the PEEK cylinder over the flexible probe and down to the base of the ValProbe RT®.

3. Insert Components:

Place both the logger and PEEK cylinder into the canister body.

4. Secure the Cap:

Guide the probe through the center cap hole, align the clips with the cylinder tabs, then press and twist clockwise until latched securely.

Performance Guidelines: Know Before You Go

Safety Tips:

- The canister is for air environments only—do not submerge in liquids.

- Exposure time should remain within safe limits as per manufacturer specifications. Prolonged exposure beyond maximum ratings can result in damage to the battery and electronics.

- After operating in high-temperature ranges, always wear protective gloves and safety glasses before opening the unit to avoid exposure to potential electrolyte leakage.

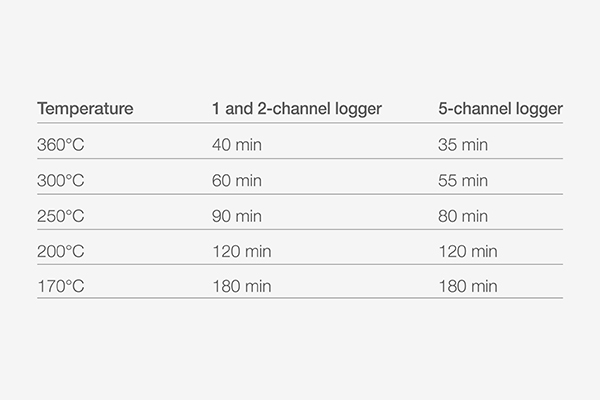

Exposure Limits:

Operational time at various high temperatures depends on stable chamber conditions and starting from room temperature. Always refer to the manufacturer's table to determine max allowable exposure durations.

Final Thoughts: Innovation Meets Extreme Environment Performance

What was once an operational barrier for real-time thermal validation has now been overcome. With the Kaye ValProbe RT® system and its high-temperature insulation canister, you can confidently perform accurate data logging in environments once considered too hazardous for battery-powered devices.

Whether you're working in pharmaceuticals, aerospace, or industrial manufacturing—this solution lets you collect real-time data in the toughest conditions, ensuring safety, compliance, and performance.